High Aluminia

When high wear resistance, high abrasion resistance, and high corrosion resistance are needed, high alumina ceramics are employed in a variety of industrial applications. If there is no thermal shock, they can even be used in high temperatures. They are produced as per customer design requirements for better application. For high rupturing capacity fuses in square and round shapes, High Alumina Hitech ceramic goods/parts are the best option. These are produced using the most cutting-edge method and are given extremely tight tolerances.

It is known for its high hardness and strong abrasion and acid and mildly alkaline solution resistance. As a result, they are a good choice for Thermostat components (used in Temperature Controllers), Thermocouple bases, Spacers, and Bobbins (used in Heaters). making them suitable for usage in corrosive conditions.

Inquiry Now| Properties | |

|---|---|

| Alumina content | 90% |

| Density gm/cc | 3.60 |

| Hardness R45N | 79 |

| Sur face Finish | 1.60u |

| Water Absorption | Nil |

| Compressive Strength : kg/cm2 | 2500 |

| Tensile Strength : kg/cm2 | 220 |

| Corrosion Resistant : mg/cm2/day with 95% H2504 @ 20 C | 0.03 |

| Max. Temp. | 1500 oC |

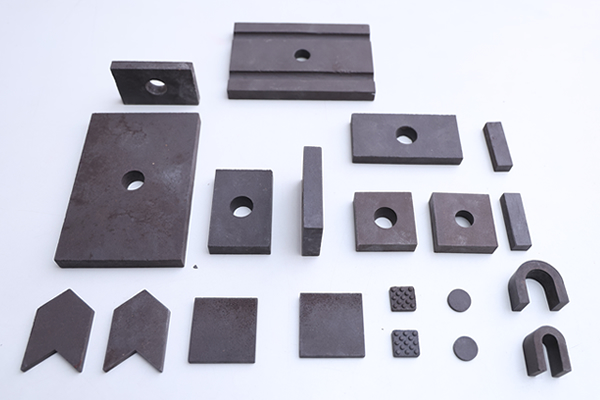

Wear Resistant Tiles and Liners

Application Chutes & Hoppers in Mineral Processing Plants; Cement and Power Plants